Detailed explanation of diamond saw blade knowledge

Feb. 12, 2025

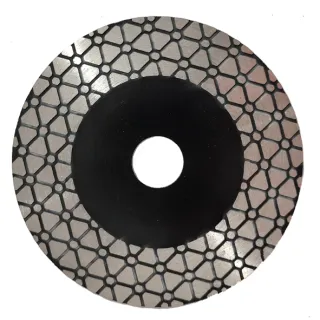

Diamond saw blade is a cutting tool, widely used in the processing of hard and brittle materials such as stone and ceramics. Diamond saw blades are mainly composed of two parts: the matrix and the blade head. The matrix is the main supporting part of the bonded blade head, while the blade head is the cutting part during use. The blade head will be continuously consumed during use, while the matrix will not. The reason why the blade head can play a cutting role is that it contains diamond. Diamond is currently the hardest substance. It rubs and cuts the processed object in the blade head. The diamond particles are wrapped in metal inside the blade head.

During use, the metal matrix is consumed together with the diamond. Generally, the ideal situation is that the metal matrix is consumed faster than the diamond, so that the sharpness of the blade head can be guaranteed and the blade head has a longer life.

Classification of diamond saw blades

More and more industries use diamond saw blades in the production process. With the integration and segmentation of the industry, the types of diamond saw blades are becoming more and more refined.

1. Classification of manufacturing process:

1. Sintered diamond saw blade: divided into cold pressing sintering and hot pressing sintering, pressed and sintered.

2. Welded diamond saw blade: divided into high-frequency welding and laser welding. High-frequency welding welds the blade head and the base together through a high-temperature melting medium, and laser welding melts the contact edge of the blade head and the base through a high-temperature laser beam to form a metallurgical bond.

3. Electroplated diamond saw blade: The blade head powder is attached to the base through electroplating.

2. Appearance classification:

1. Continuous edge saw blade: Continuous serrated diamond saw blade, generally made by sintering method, often using bronze binder as the basic matrix material, water must be added during cutting to ensure the cutting effect, and there are types that use laser to cut the gap of the blade head.

2. Head-type saw blade: The teeth are disconnected, the cutting speed is fast, and it is suitable for both dry and wet cutting methods.

3. Turbine saw blade: Combining the advantages of the previous 1 and 2, the saw teeth continuously present a turbine-like uniform convexity and concavity, which increases the cutting speed and service life.

Different materials use different types of diamond saw blades, and different powder formulas are suitable for the characteristics of different materials, which directly affects the quality, effect, qualified rate and even cost and benefit of material products.

Factors affecting the efficiency and life of diamond circular saw blades include sawing process parameters and diamond particle size, concentration, binder hardness, etc. According to cutting energy, there are saw blade linear speed, sawing concentration and feed speed.

I. Sawing parameters

(1) Saw blade linear speed: In actual work, the linear speed of diamond circular saw blades is limited by equipment conditions, saw blade quality and the properties of the stone being sawed. In terms of the best saw blade service life and sawing efficiency, the saw blade linear speed should be selected according to the properties of different stones. When sawing granite, the saw blade linear speed can be selected within the range of 25m~35m/s. For granite with high quartz content and difficult to saw, the saw blade linear speed should be at the lower limit. When producing granite tiles, the diameter of the diamond circular saw blade used is relatively small, and the linear speed can reach 35m/s.

(2) Sawing depth: Sawing depth is an important parameter related to diamond wear, effective sawing, saw blade stress and the properties of the stone being sawed. Generally speaking, when the linear speed of the diamond circular saw blade is high, a small cutting depth should be selected. From the current technology, the depth of diamond sawing can be selected between 1mm and 10mm. Usually, when a large diameter saw blade is used to saw granite rough materials, the sawing depth can be controlled between 1mm and 2mm, and the feed speed should be reduced at the same time. When the linear speed of the diamond circular saw blade is high, a large cutting depth should be selected. However, within the permitted range of saw machine performance and tool strength, a larger cutting concentration should be used as much as possible to improve cutting efficiency. When there are requirements for the processing surface, a small cutting depth should be used.

(3) Feed speed: The feed speed is the feed speed of the stone being sawed. Its size affects the sawing rate, the force on the saw blade and the heat dissipation in the sawing area. Its value should be selected according to the nature of the stone being sawed. Generally speaking, when sawing softer stones, such as marble, the feed speed can be appropriately increased. If the feed speed is too low, it is more conducive to improving the sawing rate. When sawing fine-grained and relatively homogeneous granite, the feed speed can be appropriately increased. If the feed speed is too low, the diamond blade is easily worn flat. However, when sawing coarse-grained and unevenly hard granite, the feed speed should be reduced, otherwise it will cause the saw blade to vibrate, resulting in diamond fragmentation and reducing the sawing rate. The feed speed for sawing granite is generally selected in the range of 9m~12m/min.

II. Other influencing factors

(1) Diamond particle size: The commonly used diamond particle size is in the range of 30/35~60/80. The harder the rock, the finer the particle size should be selected. Because under the same pressure conditions, the finer the diamond, the sharper it is, which is conducive to cutting into hard rocks. In addition, generally large-diameter saw blades require high sawing efficiency, so it is advisable to use coarser grains, such as 30/40, 40/50; small-diameter saw blades have low sawing efficiency and require smooth rock sawing sections, so it is advisable to use finer grains, such as 50/60, 60/80.

(2) Segment concentration: The so-called diamond concentration refers to the density of diamond distribution in the working layer matrix (that is, the weight of diamonds contained per unit area). The "Specification" stipulates that when there are 4.4 carats of diamonds per cubic centimeter of the working matrix, its concentration is 100%, and when there are 3.3 carats of diamonds, its concentration is 75%. Volume concentration indicates the volume occupied by diamonds in the agglomerate, and stipulates that the concentration is 100% when the volume of diamonds accounts for 1/4 of the total volume. Increasing the diamond concentration is expected to extend the life of the saw blade, because increasing the concentration reduces the average cutting force on each diamond. However, increasing the depth will inevitably increase the cost of the saw blade, so there is a most economical concentration, and this concentration increases with the increase of the cutting rate.

(3) Hardness of the blade binder: Generally speaking, the higher the hardness of the binder, the stronger its wear resistance. Therefore, when sawing abrasive rocks, the binder hardness should be high; when sawing soft rocks, the binder hardness should be low; when sawing abrasive and hard rocks, the binder hardness should be moderate.

(4) Force effect, temperature effect and wear and tear: Diamond circular saw blades are subjected to alternating loads such as centrifugal force, sawing force, and sawing heat during the process of cutting stone.

The wear and tear of diamond circular saw blades is caused by force effect and temperature effect.

Force effect: During the sawing process, the saw blade is subjected to axial force and tangential force. Due to the force in the circumferential and radial directions, the saw blade is wavy in the axial direction and disc-shaped in the radial direction. Both deformations will cause uneven rock cut surface, more stone waste, loud noise and increased vibration during sawing, resulting in early breakage of diamond agglomerates and reduced saw blade life.

Temperature effect: Traditional theory believes that the influence of temperature on the saw blade process is mainly manifested in two aspects: one is to cause graphitization of diamonds in agglomerates; the other is to cause thermal tension between diamonds and the matrix, resulting in premature shedding of diamond particles. New research shows that the heat generated during the cutting process is mainly transmitted to the agglomerates. The temperature in the arc zone is not high, generally between 40 and 120°C. The temperature at the grinding point of the abrasive is relatively high, generally between 250 and 700°C. The coolant only reduces the average temperature in the arc zone, but has little effect on the abrasive temperature. Such a temperature will not cause graphite carbonization, but will change the friction performance between the abrasive and the workpiece, and cause thermal stress between the diamond and the additive, which will cause a fundamental change in the failure mechanism of diamond. Research shows that temperature effect is the biggest factor affecting saw blade damage.

Abrasion damage: Due to force effect and temperature effect, diamond blades often wear out after a period of use. The main forms of abrasion damage are as follows: abrasive wear, local breakage, large-scale breakage, shedding, and mechanical scratches of the binder along the sawing speed direction. Abrasive wear: Diamond particles are constantly rubbing against parts, and the edges are blunted into a plane, losing cutting performance and increasing friction. The heat of sawing will cause a thin layer of graphitization to appear on the surface of diamond particles, greatly reducing the hardness and aggravating wear: the surface of diamond particles is subjected to alternating thermal stress and alternating cutting stress at the same time, fatigue cracks will appear and local breakage will occur, revealing sharp new edges, which is a more ideal wear form; large-scale breakage: diamond particles are subjected to impact loads when cutting in and out, and the more prominent particles and grains are consumed prematurely; shedding: the alternating cutting force causes the diamond particles to be constantly shaken in the binder and become loose. At the same time, the wear of the binder itself and the sawing heat during the sawing process soften the binder. This reduces the holding force of the binder. When the cutting force on the particles is greater than the holding force, the diamond particles will fall off. Either type of wear is closely related to the load and temperature borne by the diamond particles. Both of these depend on the cutting process and cooling and lubrication conditions.

179

0

0

None

None

Comments

All Comments (0)